So while a machinist would need to interpret or convert an AutoCAD design file, SOLIDWORKS models are instantly readable by computer numerical control (CNC) machines and 3D printers.

#Autocad vs solidworks update

Any future changes to the model also update each statement and layout automatically.įinally, SOLIDWORKS can export design files that a manufacturing facility can use directly.

Because SOLIDWORKS users are working with a 3D model, it’s easy to choose which views or cross-sections should be projected onto a 2D format.Īs other designers add their parts of the model, the layout and design views update automatically. SOLIDWORKS can also quickly create AutoCAD-style 2D drawing layouts. This intelligent design is becoming an industry-standard in the 3D CAD world and is an essential feature in any modern, high-end 3D CAD system such as SOLIDWORKS. This enables designers to make quick changes to the model.ĭesigners can even use formulas to specify dimensions and angles relative to other features. Parametric modeling records design features or constraints and then applies them to other parts of the model.

SOLIDWORKS also uses the parametric modeling system approach to 3D CAD.

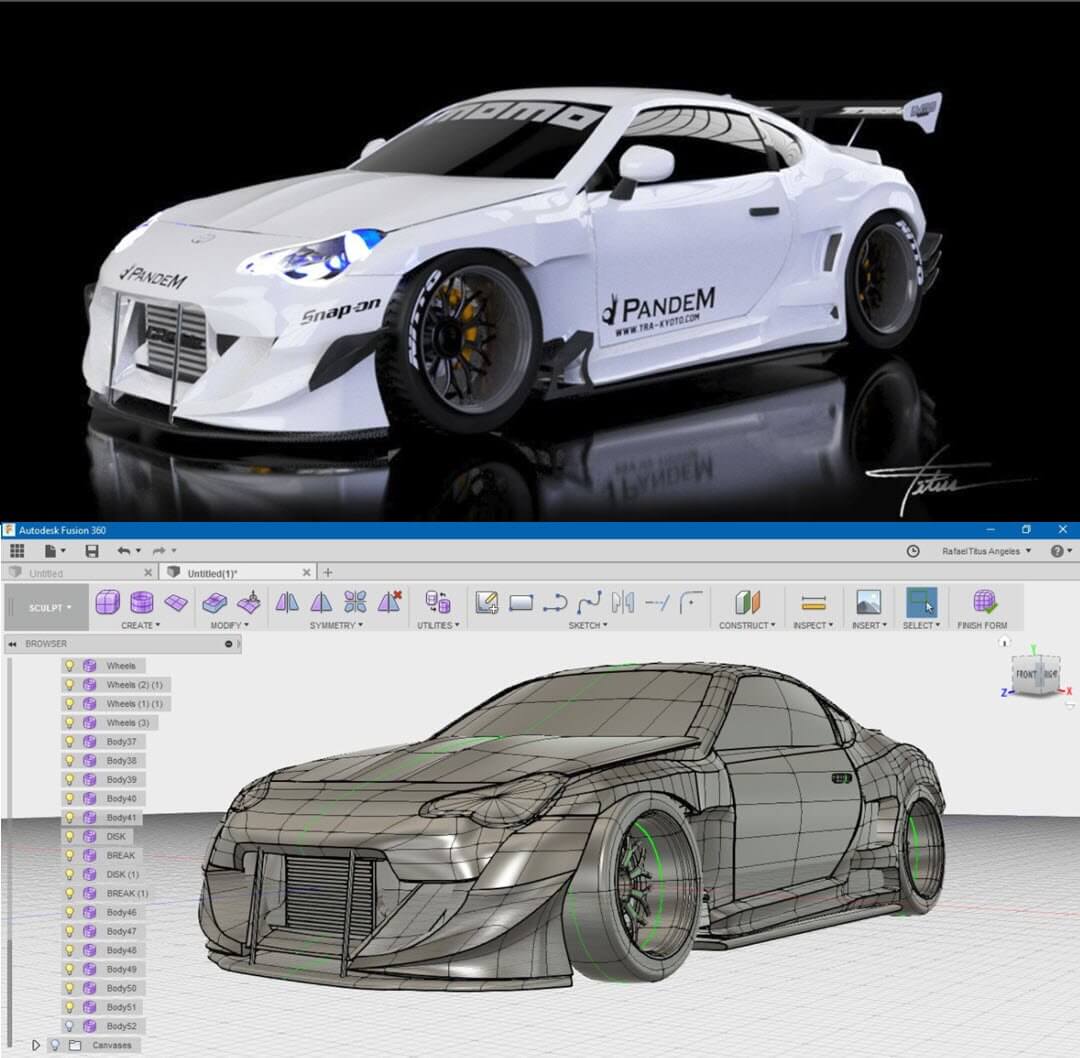

#Autocad vs solidworks movie

The user can then export the presentations as image or movie files and send them to the client for approval. SOLIDWORKS can output each design with realistic materials and lighting, which allows the user to create presentations using the electronic model. A single CAD manager then checks each designer’s component and sends feedback about product compliance and tolerances as needed. Using 3D modeling packages such as SOLIDWORKS, each designer can work on their part of the design separately. In a large, complex project, it’s normal for many designers and organizations to be involved in the design process. The designer can also identify and resolve problems early in the design process, decreasing costs and time delays. SOLIDWORKS also contains tools to simulate object movement and ensure that the final product will work and move exactly as intended.Īll of this means that designers can virtually test the entire product design before starting real-world production. They can also use SOLIDWORKS to check product clearances and tolerances between different component designs. Hirschtick himself remained involved in the company for another 14 years before leaving to found Belmont Technology which later became Onshape, another 3D CAD package currently growing in popularity.ĭesigners use SOLIDWORKS for more than just publishing design information. SOLIDWORKS was acquired by aviation manufacturer Dassault in 1997 and has since become one of the leading 3D CAD packages in the mechanical engineering industry. The idea was to create a 3D CAD Package that was both affordable and easy to use. SOLIDWORKS was first released in 1995 by MIT graduate Jon Hirschtick using money gained from being part of the famous MIT Blackjack Team. The only difference between drawing in AutoCAD and drawing by hand is that AutoCAD is done on a computer. Different views, sections, and projections are drawn separately. AutoCAD users today follow the same technical drawing rules they used before.ĭesigners create lines to represent real-world objects and text to describe those objects. While it has 3D capabilities, too many, it remains primarily a 2D drawing tool.

#Autocad vs solidworks software

AutoCAD is the common starting point for every designer.ĪutoCAD: Still the most widely used for 2D drawingĪutoCAD has continued to develop and remains the most commonly used CAD software today.AutoCAD: Still the most widely used for 2D drawing.

0 kommentar(er)

0 kommentar(er)